Prime Mapping: Taking precision to the next level in Australia

When a major oil and gas operator sought technological support to develop a natural gas field off the coast of Australia, Vallourec answered the call. Combining deep expertise with its Prime Mapping solution, Vallourec helped precisely measure the casing ID to ensure that it matched the packer settings and tolerances – eliminating costs and saving time in the process.

A major oil and gas operator was looking for technological support to develop a natural gas reservoir located off the West coast of Australia. The project involved installing 109 pipes in water depths of 165 meters, requiring precise internal diameter (ID) pipe measurements to ensure a smooth packer setting installation. Having heard about the abilities of Prime Mapping to generate accurate pipe measurements, the operator enlisted Vallourec’s support.

A crucial part of downhole equipment, the packer is a sealing device that contains fluids and pressures within the tubing string. Running a packer inside a well is a critical operation to ensure well integrity and can be challenging. That’s where Prime Mapping comes in: by helping operators verify pipe measurements, this technology enables them to ensure which pipes are the best fit for the packer, thus improving the packer setting and minimizing integrity risks.

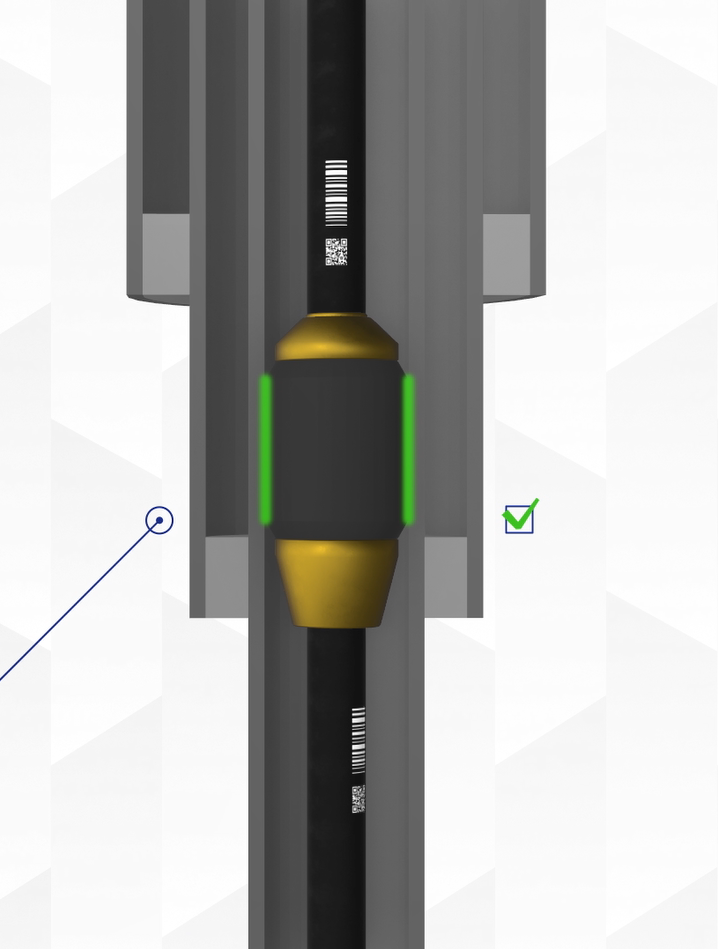

Prime Mapping service is delivered thanks to a proprietary In-pipe Laser Rover tool. Operating wirelessly under the control of a technician, the Laser Rover runs the length of each pipe, generating detailed ID and ovality measurements. The rover then relays this data to the technician’s computer for readout. This solution enabled the Vallourec team to register accurate casing geometry dimensions, all in digital format, to ensure successful project delivery.

“Being able to get accurate dimensions is an asset, especially given that offshore platforms are costly to operate on,” says Bala Rajoo, the Vallourec Operations Manager who carried out the Prime Mapping service on site in Australia.

By using Prime Mapping, you’re saving time that may otherwise be spent redoing operations in the event that a packer setting fails pressure tests.

While Bala carried out field operations, research and development (R&D) expert Sébastien Petit ensured that data was accurately collected, analyzed and reported. “Prime Mapping supplements our expertise, enabling everyone to fine-tune procedures and perform at an entirely new level,” Sébastien says. “The In-pipe Rover gives us a greater range of vision, but the value comes from understanding and interpreting the information we receive. Simply put, it improves decision-making thanks to enhanced data.”

More precision with Prime Mapping

Prime Mapping has set a new industry standard in operational precision and efficiency. “Our customer needs to have absolute control in terms of project quality,” says Gabin Esquibet, South East Asia Services Director.

Prime Mapping makes that possible. With it, we can deliver 60,000 ID measurements per pipe with a resolution accuracy up to 0.1 millimeters. That speaks to our goal of giving operators the most accurate pipe measurements possible for their casing and tubing.

Benefits extend beyond mere industry-standard compliance. Prime Mapping also helps identify small changes in the pipe ID which, even if they are within specification, can be detrimental to the packer setting. “Compromising the uniformity of a pipe, even in subtle ways, can lead to reduced packer integrity, creating leakage risks,” Bala says.

Compatible with any pipe manufacturer, Prime Mapping can be performed on the rig, or directly at the customer’s yard to eliminate transport costs.

In addition to helping field technicians select the most suitable pipes for packer fit, Prime Mapping is also able to strengthen well integrity through improved bore volume calculation for cement displacement operations. This allows them to know exactly how much cement is needed to be injected or displaced, and when the plug will bump at the end of cementing. “Improved calculations mean greater well integrity,” Gabin says. “That makes our work indispensable in today’s energy sector.”

Prime Mapping is seeing potential for expansion and active application planning in other regions around the world. For example, it garnered considerable interest at the International Offshore Technology Conference Asia (OTC Asia) in Malaysia in February, where Vallourec showcased the solution among other innovations. “Fortunately, we are ready,” Sébastien says. “Prime Mapping has proven its speed and resilience in handling 109 pipes weekly under 45° C heat for our customer’s wells. In ideal conditions, we could inspect 50 pipes a day,” he notes, illustrating prospects for rapid deployment in large-scale projects.

Prime Mapping has proven its speed and resilience in handling 109 pipes weekly under 45° C heat for our customer’s wells. In ideal conditions, we could inspect 50 pipes a day.

Small discoveries create big impact

As the team sees it, Prime Mapping is poised to deliver far beyond meticulous data and better pipe selection. “The solution means better well integrity, improved environmental safety and better operations globally,” Gabin says. “Through Prime Mapping, we’re on the fast track to elevating industry standards.“

Beyond Prime Mapping, Vallourec supports Tubular Repurposing

Beyond the acquisition of ID measurement, and thanks to its extensive Non-Destructive Testing (NDT) expertise, Vallourec has developed other In-pipe Rover tools for pipe inspection. These devices are equipped with UT (Ultrasound Technology) and Eddie Current technologies in order to assess the wall thickness of the pipe and identify any defects such as pitting or cracks.

These advanced tools support a new service called Tubular Repurposing, which allows operators to assess and reuse existing sleeping stocks, leftovers, or pulled out items during or at the end of a project. The benefits of Tubular Repurposing are clear for operators: it boosts cost recovery and cost-effectiveness while minimizing environmental impact at the end of a project, repurposing surplus.